Building A Greener Planet

Acoustic Sensors Air Quality Alternative Fuels Biodiesel Biosurfactant Carbon Cleaner Earth Climate Change Conservation Emission Reduction Energy Environmental Stewardship Fossil Fuels Global Warming Natural Gas Hydrates Nitrogen Oxide Reduction Pollutant-Control Power Sea Floor Maps Sequestering Methane Sub-bottom Profiling Sustainable Undersea Vehicle Research The University of Mississippi

For Ole Miss researchers, environmentalism is not a trend, not a fashion to follow, not an excuse to buy new bamboo sheets or carbon credits from a dubious Web site.

The engineers, chemists and biologists who have dedicated their careers to searching for alternative fuels, reducing emissions or mitigating water pollution are just glad the rest of us are finally catching on.

Contradiction

In 2007 and 2008, Dr. Wei-Yin Chen taught the first ever Ole Miss course on climate change, stood with the university chancellor as he signed the American College and University Presidents’ Climate Commitment, suggested that the governor join the Governors’ Declaration on Climate Change, requested that faculty members incorporate climate change into many academic disciplines and asked that faculty members who tackle climate change receive incentives.

Not bad for a guy who’s been doing fossil fuel research since the 1970s.

“The first thing I told my students in the climate change course is that I’m actually a polluter,” Chen said, laughing.

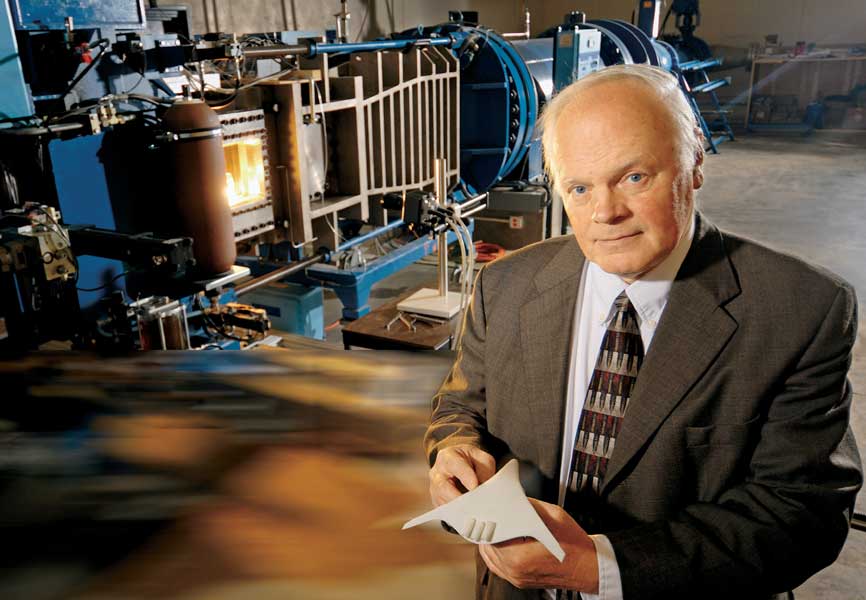

Actually, what seems like a contradiction really isn’t. Chen, a chemical engineering professor, has spent the last three decades finding ways to make coal burn cleaner.

“In the ‘70s, we were worried about sulfur dioxide, so I worked on that. In the ‘80s, nitrogen oxide (NO) was a big issue, so that’s when I began to work on NO reduction,” Chen said. While other researchers tackled mercury oxide and methyl mercury from coal in the 1990s, Chen perfected his work on nitrogen oxide reduction, starting at the very beginning by better understanding coal’s reaction chemistry. He then was able to devise more effective reburning techniques that reduce nitrogen oxide—the major contributor to smog—by a much larger percentage than before.

“During that four-year project, we generated new improvements every year,” Chen said.

The next step, Chen said, is to develop multifunctional pollutant-control technologies that can effectively reduce sulfur, mercury, nitrogen oxide and carbon dioxide from coal-fired power plants. That’s important for the United States, where coal fuels more than 50 percent of the nation’s energy needs, but also important to China, an emerging world power that depends on coal—and whose air quality has deteriorated exponentially in the last 10 years.

Chen recently visited a major power plant in Beijing to consult on emission reduction. With energy demands rising around the globe, Chen’s work is more important than ever.

“In 2007, it cost $6 to produce 1 million BTU of energy using petroleum fuels. To produce the same amount using coal, it cost $1,” Chen said. “Coal is a wonderful source of energy—but only if we use it right and find a way to handle the emission problems.”

So Chen’s dedication to mitigating climate change isn’t such a contradiction after all. It makes perfect sense, then, that an editor at Scribner has asked Chen to edit a book, Mitigating Climate Change. Co-edited by Dr. John Seiner, associate director at the National Center for Physical Acoustics and mechanical engineering professor on campus, the book will feature chapters from Ole Miss mechanical engineers, civil engineers, chemists and biologists, as well as some outside and multidisciplinary experts.

For an unapologetic coal burner, that’s pretty impressive.

Harvesting Alternative Fuels

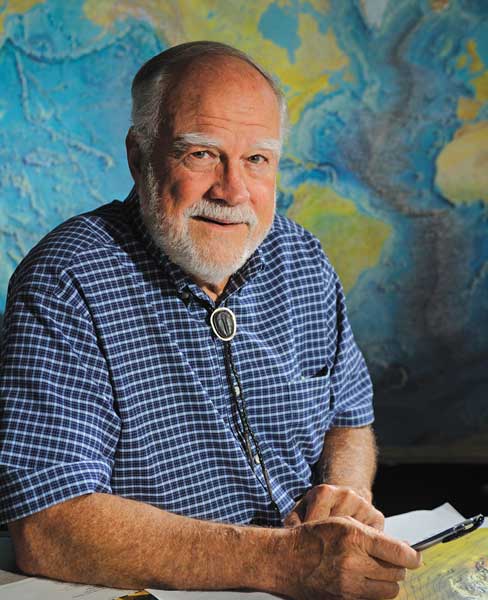

From collecting old cooking oil for powering his truck to harvesting natural gas hydrates from the ocean floor for powering the world, geology professor Dr. Robert Woolsey dedicated his career to finding viable, safe alternatives to petroleum and to leaving behind a cleaner earth.

Tragically, Woolsey’s incredible life was cut short by a July 2008 car accident. Friends mourned the passing of the 72-year-old father of seven. Carol Lutken, a longtime colleague, remembered Woolsey was truly “gifted with people. He fueled your enthusiasm,” she added. “He could inspire you to explore new directions, to take your work where you never thought you’d go.”

Woolsey led three research groups at Ole Miss that will carry on his legacy: the Mississippi Mineral Resources Institute (MMRI), the Center for Marine Resources and Environmental Technology (CMRET) and the Seabed Technology Research Center, part of the National Institute for Undersea Technology (NIUST), also based at Ole Miss and funded by the National Oceanic and Atmospheric Administration (NOAA).

Research and curiosity took Woolsey in a lot of different directions—from designing and building a naturally safe and ecologically friendly wastewater treatment for friends at his favorite vacation resort in Belize to making his own biodiesel on campus after fuel prices took a major chunk of his research budget.

“We took care of ourselves, and now we’re also making biodiesel for the landscape service on campus,” Woolsey said in an interview just two weeks before his death. “But spent vegetable oil isn’t viable for everyone—it’s not sustainable—so we’re actually looking at ways to produce biodiesel with algae.” Brad Crafton, a UM student and research technician at CMRET, worked on this project with Woolsey and continues to work on it now.

When asked about his wide-ranging approach to alternative fuels and conservation, Woolsey laughed. “We’re not proud,” he said. “Anything that works. If we’re going to survive, we’ve got to bring a lot of different solutions in. There isn’t just one answer.”

Woolsey’s biodiesel project grew out of his legendary enthusiasm and the inspiration of working with Crafton, an ardent environmentalist, Lutken said. Chiefly, his life’s work—work that continues through his research groups and colleagues—focused on simple solutions to big problems.

As a geologist and marine mining engineer, Woolsey’s career spanned the globe and included the recovery and research of a wide range of mineral resources. Gas hydrates, a solid form of natural gas and water formed under high-pressure/low-temperature conditions in deep water, were one of the greater passions in his later years. Geologists estimate the ocean floor contains twice as much natural gas hydrates as all the earth’s coal, oil, gas and other forms of natural gas combined.

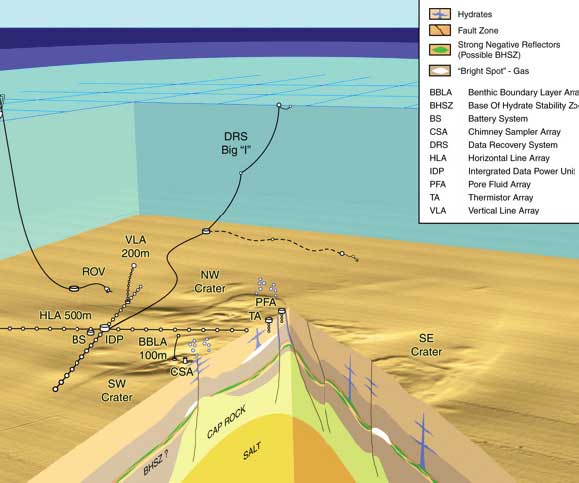

Woolsey directed efforts to form a consortium of scientists with interests and expertise in gas hydrates in the Gulf of Mexico. The group has representatives from several countries in the fields of academia, industry and government, and is now in the process of deploying a seafloor observatory, the first in the world devoted to the study of gas hydrates.

Until recently, gas hydrates were more of a nuisance than anything else, causing seafloor instability that cost Shell Oil $200 million in a matter of minutes when hydrates shifted and liquefied, bringing a drilling platform down to the bottom of the Gulf of Mexico. The Department of Interior funded Woolsey’s first study of hydrates as a potential hazard.

Lutken, CMRET’s acting director, is a geologist who aids gas hydrates research along with Dr. Tom McGee, a geophysicist in the group.

“I study the geological framework where gas hydrates are known to occur in order to predict where else they might be,” Lutken said. McGee developed a data-gathering system that CMRET researchers are using to develop a method for identifying gas hydrates on seismic records and thereby predicting their exact location on the ocean floor.

Working together, Lutken, McGee and others can save lives and prevent the destruction of expensive equipment. Once a hydrate-prone area is identified, seismic surveying and monitoring systems will be used to pinpoint exactly where the hydrates are.

“Rather than risk millions of dollars of equipment and put people in harm’s way, we hope to supply the capability to decide whether a platform location is safe or whether moving it a few thousand feet to a safer location is necessary,” Lutken said.

But the Department of Energy also became interested in CMRET’s hydrates work as a potential homegrown energy resource.

We can’t mine hydrates, which “are like the caulk in a leaky ship,” Woolsey said. “Release them, and methane is vented into the ocean and atmosphere, which defeats the whole purpose, really.”

Instead, Woolsey’s team has been figuring out how to trap them.

More than six years ago, consortium researchers began studying how and why natural gas forms solids with sediments on the ocean floor. They found the vented gas needed some kind of biosurfactant to stick to as a framework for its structure. They also studied the seafloor, pinpointing where gas is vented. If tanks with biosurfactants are placed near the vent, hydrates form inside the tank. One cubic foot of hydrates expands to 170 cubic feet of quality methane gas.

Woolsey, ever the engineer, was already thinking about how this research could be scaled up to help mankind.

“He was always looking into the future,” Lutken said. “Always asking, ‘How could this be done one day?’”

Woolsey speculated that a barge could be used to capture huge amounts of methane on the ocean floor, then keep the contents chilled and under pressure for transport.

“You’d be sequestering methane that would normally be vented into the atmosphere, providing a considerable amount of clean natural gas for use and employing people in this country instead of sending money and jobs elsewhere,” he said.

It’s a great idea, Lutken said, one Woolsey left in the very capable hands of fellow scientists inspired by his work and his vision.

The Yellow Submarine

All those deep-water seafloor studies require getting close enough to the seafloor to do meaningful work. Woolsey’s team has help on that front from Ray Highsmith, the director of NIUST and the university’s Field Station. Through NIUST and its Undersea Vehicles Technology Center at the University of Southern Mississippi, Highsmith coordinated the procurement of the Eagle Ray, a 16-foot-long, bright yellow unmanned undersea vehicle that uses acoustic sensors to provide high-resolution seafloor maps and sub-bottom profiling.

Highsmith, a marine scientist, helped study and mitigate the impact of oil spills in Alaska, where he lived and worked prior to moving south to manage the UM Field Station and its affiliates, the Center for Water and Wetland Resources and NIUST. The UM Field Station, just a few miles from the Ole Miss campus, is a 740-acre wildlife research and education facility. Research being conducted at the Field Station includes using rice plants to clean pesticides from streams and looking for new, health-related chemicals in plants that grow naturally, furthering the vision of promoting environmental stewardship with innovative community outreach programs.